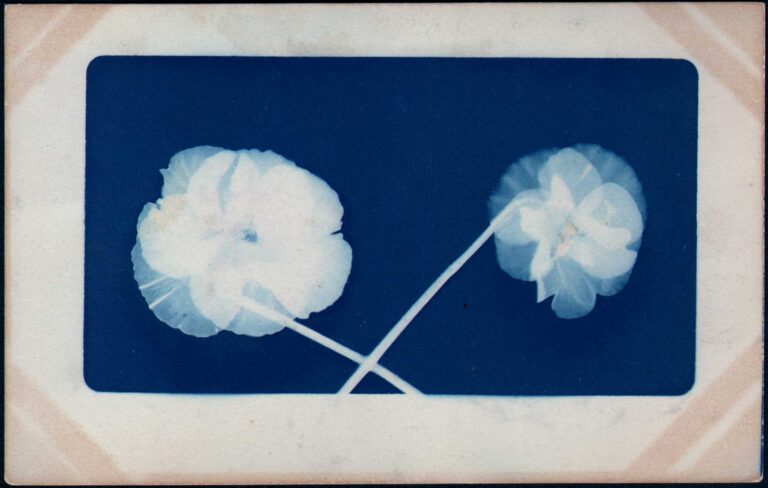

Diptych: Fern Studies

Two individual fern studies paired as a diptych. They resemble ornamental Coastal Wood ferns, (Dryopteris arguta) and are most likely from the early 20th Century. They were probably made using commercially available sensitized blueprint cloth, with details outlined below.

The Two Johns: Herschel & Mercer

Although Englishman John Frederick William Herschel gets the credit for discovering the cyanotype process in 1842, author Mike Ware notes it was Manchester, England color chemist and calico printer John Mercer (1791-1866) who “has the distinction of being the earliest observer (in 1828) of the photochemical formation of Prussian blue; but he did not follow up this discovery until 1847, when he evolved the following method for obtaining negative cyanotypes:

“I found that if paper or cotton cloth is smeared with a solution of pernitrate or persulphate of iron with certain quantities of oxalic and tartaric acids, dried in the dark, then exposed to the light (solar), and immediately dipped in solution of red prussiate containing a little free sulphuric acid (preferably free from yellow prussiate), where the light has caused deoxidation, the blue is fixed, and where the peroxide remains unchanged there is no colour. The cloth or paper must be washed immediately in water containing a little sulphuric acid, and afterwards in pure water. The picture is a reverse blue print.”

Ware continues: “Mercer’s business commitments allowed him little time for progressing these experiments until 1854, when he began to produce striking, richly coloured prints on paper, and cotton fabrics especially, which were exhibited at the annual meeting of the British Association for the Advancement of Science, in Leeds in 1858.” (1.)

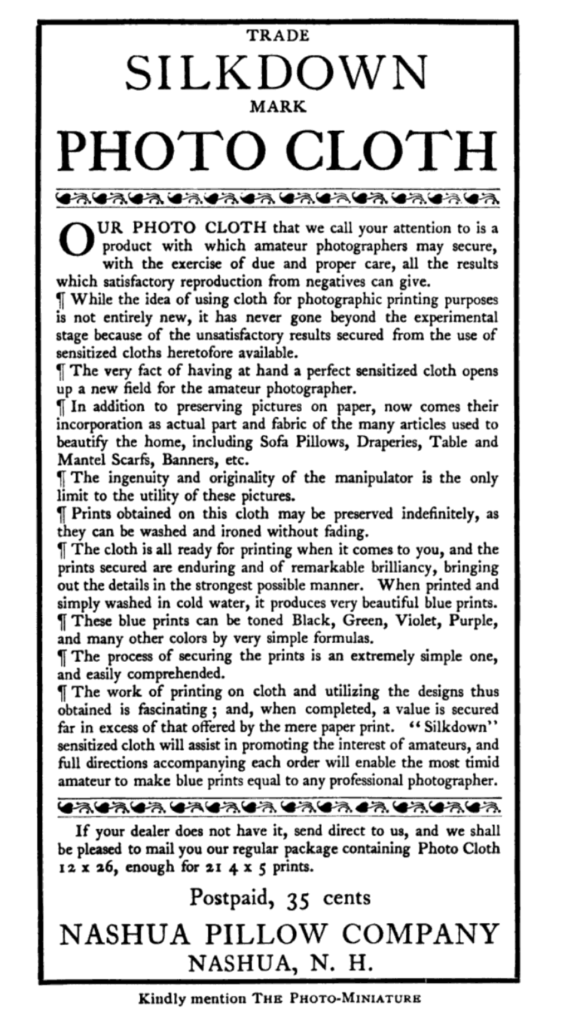

Commercially Sensitized Textiles for Cyanotype: Silkdown Blueprint Cloth: 1880-1920

While the first commercially prepared cyanotype paper didn’t became available until 1872 in France, where it was produced by Marion et Cie in Paris under the name papier ferro-prussiate, (2.) sensitized textiles for cyanotype came later. By 1900, keen amateur photographers could even make their own, by purchasing the trademarked textile known as Silkdown blueprint cloth through the mail.

Ware notes in his volume, Cyanomicon: “The process of making cyanotypes on fabrics to provide photographic decoration for quilt-covers and cushions became quite popular in North America in the period 1880-1920, and even built up to a minor industry, as is evidenced by at least one commercial catalogue, from the Nashua Pillow Company of New Hampshire, which offered for sale several cushion covers illustrated with cyanotype scenes of natural beauty or national and patriotic significance. The catalogue proudly declares that: “There is no happier combination of ornamentation and usefulness for the Home Beautiful, than a Blue Print Sofa Pillow Top.”

He continues: “The Nashua Pillow Company also offered a service for transferring the customer’s own negatives into cyanotype prints on prepared fabric. The assertion is made in this catalogue that, in terms of brilliance and permanence, the cyanotype prints on cloth were superior to those on paper, although it is hard to understand the basis of this claim. A fine specimen of this genre, which is probably one of the Nashua Pillow Company’s products, can be seen in the collection of the National Gallery of Canada: a cushion cover bearing twelve cyanotypes of unidentified coastal landscapes. (369) The rediscovery of other specimens of the Nashua Pillow Company’s products has been recently reported. The company also offered its sensitized blueprint cloth for sale in 1900, under the registered trade mark of ‘Silkdown’, at 75 cents per square yard. (3.)

Silkdown Photo Cloth in The Photo-Miniature & Process Photogram and Illustrator

The following editorial comment for Silkdown appeared in the March, 1900 issue of The Photo-Miniature: Silkdown, the new, ready-sensitized “blue print” fabric introduced by the Nashua Pillow Company, Nashua, N. H., is very much in evidence at the stores of the dealers at present. The examples shown are extremely effective and lend themselves to decoration in a happy way. If enterprisingly “pushed” this specialty should find wide popularity among amateurs, as well as for commercial work where paper prints are sometimes inconvenient to handle. p. 633

And from the August, 1900 issue of the Process Photogram and Illustrator:

Silkdown Photo Cloth (Nashua Pillow Co., 6-18 Pearson’s Avenue, Nashua, N.H.) is a fine strong fabric sensitised with ferro-prussiate. It prints rapidly and gives blue prints of good vigor, the makers specially recommending it for the production of pillow cushions, etc., for which purpose they supply a toning solution, which, it is claimed, enables the print to withstand washing in soap and water. Turnbull’s blue, as is well known, is decomposed under these conditions Prices: cloth per packet, 35 cents; toning solution, 25 cents. Postage extra to England. p. 26

Full-page advertisement for Silkdown Photo Cloth published in The Photo-Miniature, March, 1900

By later in 1903, Silkdown became popular enough that it was spun off by the Nashua Pillow Co. to become the Silkdown Company, based in Boston. From the October 15, 1903 issue of The American Machinist:

Blueprint Cloth.

Many of our readers will thank us for calling their attention to a photo cloth which may be used as a perfect substitute for blueprint paper, with several additional advantages of its own. It is named “Silkdown” photo cloth and it can be printed from negatives or tracings precisely as blueprint paper is used, and by the use of certain chemicals various other colors may be produced besides the blue. It is practically indestructible. It can be rolled, folded or wadded up like a pocket handkerchief, and if soiled it can be washed. It is made for the amateur and professional photographic trade and is not generally known to engineers. We have seen a number of prints from it, which were as clear and sharp as any we have seen on blueprint paper. The cloth is of course more expensive than paper. The manufacturers are The Silkdown Company, Everett Station, Boston, Mass. p. 1453

Commercial Products: Blue Print Powders for Textiles

A more economical way for those wishing to create cyanotypes on textiles involved supplying their own and purchasing a tube of “blue print powder”, which was mixed with water and applied to the fabric. The following are a a few powders identified from secondary sources.

1902: Wayne Chemical Co., Germantown, Philadelphia

Blue Print Powder

For making prints of a blue color on silk, satin, linen, nainsook or paper. Tube makes sufficient solution to sensitize 100 sq. ft., of paper or 50 sq. ft. of cloth. Price 25¢

From your dealer, or will be sent by mail, postpaid, on receipt of price. Source: The Saturday Evening Post, April 12, 1902

–The manufacturer E. W. Newcomb of Stamford, CT marketed a “blue print powder” which was most likely also compatible with textiles: “The blue print powder and persulphate are in sealed tubes, the contents of which need only to be dissolved in the requisite quantities of water to give solutions ready for use” source: The American Amateur Photographer, July, 1902, p. 332

1904: Burke & James, a large photo stock house based in Chicago, advertised their Cyanine brand powder:

CYANINE

A Blue Print Powder Sensitizer, which when dissolved in water and applied to cloth, postal cards or paper, produces a fine photographic blue print surface. Its simplicity and the beautiful results obtained recommend it to all.

PRICES

1 ounce bottle……. .$0.15

4 ounce bottle…….. .45

8 ounce bottle…….. .85

16 ounce bottle……. 1.50

Source: The Practical Photographer, November, 1904

1909: Ingento Brand Blue Print Powder, by Burke & James, Chicago, IL

Description at History Colorado Collection:

Ingento Blue Print Powder Tube: Object ID 87.154.27.B

“Tube shaped container is made of glass and has a cork stopper at the opening of the tube. The blue powder appears to still be in the glass tube. The white label covers nearly the entire tube and is in good condition. There is dark blue text on the label, describing the product as well as instructions for how to use the powder.”

Inscription

INGENTO // BLUE PRINT POWDER// TRADEMARK// FOR MAKING BLUE PRINTS / WRITING PAPER, POSTAL/CARDS, ENVELOPES, /AND ALL KINDS/OF FABRICS/DIRECTIONS FOR SENSITIZING/Dissolve contents of this tube in one/ounce of water. Coat the material to be/used with a tuft of cotton or a brush./ Hang up to dry in a dark place. When /dry, print and wash the same as ordinary/Blue-print paper./ Keep solution in the dark for fu-/ ture use./ Burke & James / Chicago

Instruction Sheet: Directions for Ingento Blue Print Powder: Object ID 87.154.28.C (no active link: please search within field for Burke & James: Object ID 87.154.27.B)

Description

Paper instruction sheet is folded into quarters, and was stored rolled around the tube to fit into the rectangular box. When unfolded the corners curl from being rolled around the tube, and deep creases are evident. The paper is an off-white color with navy blue text. An example photo appears near the upper left corner of the insert to demonstrate the effects of using blue print developing powder.

Inscription

INGENTO/ BLUE PRINT/ POWDER/ TUBE// There are no more/ attractive or artistic prints than Blue Prints/ when the blues are bright/ and the whites are clear, nor/ is there any printing process/ so simple to manipulate or so/ inexpensive. Blue Prints can/ be made on almost any ma-/ terial, such as note paper, en-/ velopes, cards, silk, linen, can- /vas, etc., with little time and / ordinary care.// The best results are obtain-/ed when the material is used/ freshly coated, and the chemicals are pure.//[bolded] The Directions [bolded] for preparing the material are very simple, and may be given/ briefly as follows:–Dissolve the contents of one tube in 1 oz of water, coat, dry, / and print in the ordinary way; but to prevent failure we give all of the necessary/ precautions as follows:// Use pure water if possible; distilled, rain, or well boiled water. Filter the/ Solution through a linen cloth and coat the paper or cloth in a dim light with a / clean sponge, tuft of cotton or brush, and then hang up to dry in a dark place./ Make the prints while the material is freshly coated. Print in ordinary print-/ ing frames. Prints should be made rather deep so as to allow of ample washing/ afterwards. When the printing is done all that is necessary is to give them a/ thorough washing in running water. They may be dried between blotters, or/ mounted wet. When a small portion of cloth is to be sensitized it is better to use/ embroidery hoops. The Solution should be kept in a small bottle inside of a small/ dark box, as it will deteriorate if exposed to a strong light. // TONING BLUE PRINTS// Blue Prints may be toned to sepia, chocolate, or even black, at any time, by/ the following method:–Immerse the print in a saturated solution of Sodium Car-/bonate until the image has disappeared; wash in several changes of water, and/ then transfer to a saturated solution of Tannic Acid. The longer it is left in this / solution the deeper the tone will be. After toning, they are washed in the usual/ manner; dried and mounted–no fixing required.//Price, Per Tube—10 cents// BURKE & JAMES//CHICAGO//

1913: Sears, Roebuck and Company, Catalog No. 122

Preparations and Chemicals

Blue Print Powder, 13 Cents.

No. 20F | 933 This Blue Print Powder is a preparation for sensitizing paper, cloth, cards or for materials for making blue prints. The powder is merely dissolved in water and the solution applied to the paper or cloth with a camel’s hair brush. With this preparation you can make the prints on any kind of paper, including your (?) paper, or on cloth of any kind, making (?) blue pictures for sofa pillows, tidies, ban-(?) etc. Shipping weight, 3 ounces. Price per 1-ounce bottle, sufficient for 8 ounces. 13¢

- Mike Ware, 4.4.2 John Mercer’s ‘chromatic photographs’, in: Cyanomicon: History, Science and Art of Cyanotype: Photographic Printing in Prussian Blue, revised, 2020: p. 95-6

- Cyanotype: The Atlas of Analytical Signatures of Photographic Processes, Dusan C. Stulik & Art Kaplan, 2013, The Getty Conservation Institute, Los Angelas, CA, p. 5

- Ware: Cyanomicon: History, Science and Art of Cyanotype: Photographic Printing in Prussian Blue: pp. 111-12